The color code sensor's job is to find predefined markers on an object that are only slightly different in color from the rest of the background. In many packaging processes, these contrast marks must be reliably identified on film, pouch and blister packages or labels. The KRT 18B series color code sensor combines simple operation achieved by fixed signal display with high performance. In addition to our existing models that use RGB light sources, we now offer color scale sensors that use white light, which complements the portfolio and expands it with additional instructional models. These products can be adjusted quickly and visually via potentiometers or teach buttons, remotely via cable or IO-link, and provide continuous feedback on contrast quality using a unique bar graph display. High precision contrast detection is performed with short response time and small signal jitter. RGB devices also provide analog output signals that are suitable for particularly harsh mark detection tasks.

Your benefit

Multi-color (RGB) or white light (W) models provide optimal mark recognition performance on brightly printed or luminous films

White light provides higher reliability in identifying contrast marks on luminous surfaces

Multi-colour (RGB) provides better performance when processing brightly coloured printed films

Free choice of adjustment mode: Intuitive detachable potentiometer, quick and accurate adjustment through the instruction button. Of course, it can also be taught remotely via cable or IO-link

Dual channel IO-link: For monitoring, diagnostics, and easy switching when changing recipes

The three instruction levels ensure that each application has a perfect tuning program

Static 2 point instruction for the mark and background when the conveyor belt is stationary

Carry out dynamic 2 - point instruction while the conveyor is running

Static 1 - point instruction recognizes arbitrary contrast marks before uniform background

The signal is permanently displayed through a self-adjusting bar graph on the back of the sensor

Tracking feature with threshold tracking to identify faded contrast marks

Fine-tune the toggle threshold by teaching "proximity markers" or EasyTune (T)

Models with horizontal or vertical light spots

13 mm + -3 mm flexible operating range

Maximum switching frequency up to 22 kHz/response time 20 µs

Small compact case made of nickel-plated metal, IP67 and IP69K and ECOLAB

application

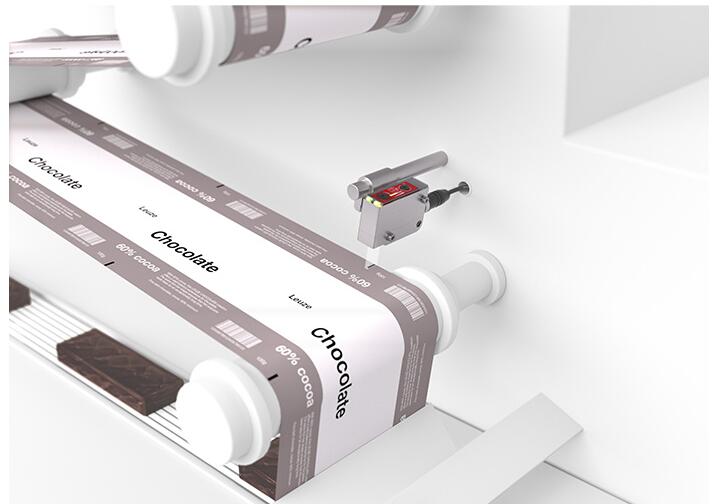

Identification of cut marks of packaging film during film feeding

Requirements:

In a horizontal tubular bag packing device, the product is wrapped by winding. Packaging film must be cut accurately to size. The packaging film is treated for beats by identifying contrast marks, which may have a different color and sometimes only slightly different from the printed pattern on the film.

Solution:

The new white light specification KRT 18BW color scale sensor reliably recognizes contrast markers of various colors, even on glowing backgrounds. At the same time, dynamic 2-point instruction can complete sensor setup while the film is running. You can use tracking to compensate for faded print marks, such as those near the end of the film roll.